How Tennessee Whisky Is Made

tennessee | travel | whiskey | whiskeys

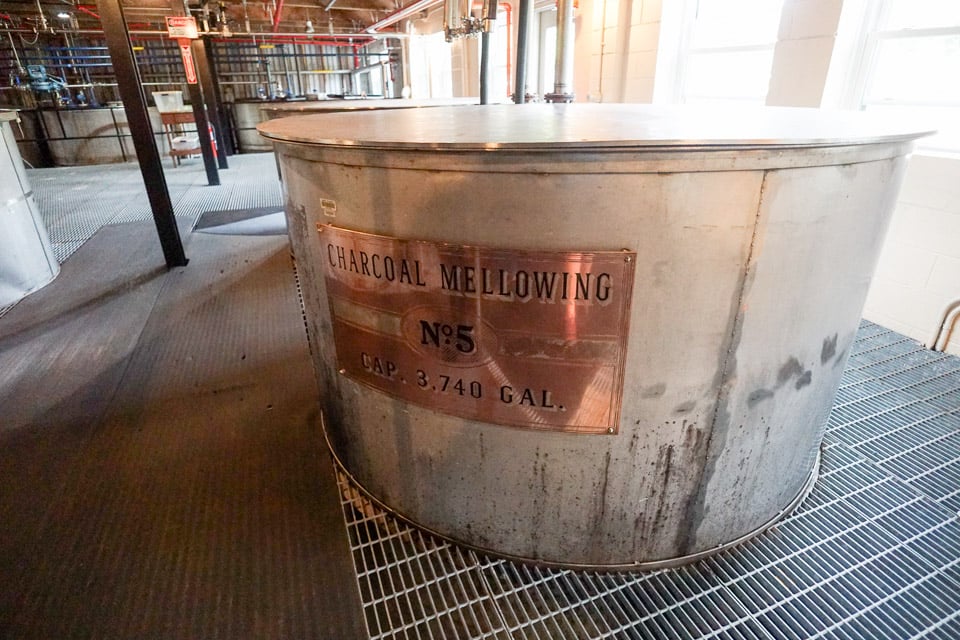

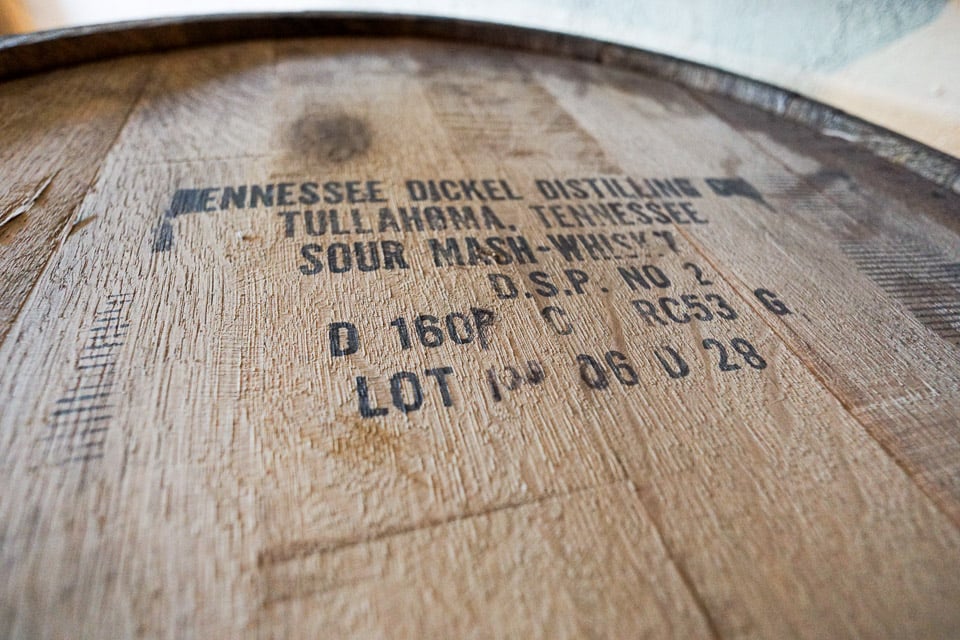

We recently had the privilege of visiting George Dickel Tennessee Whisky’s famous Cascade Hollow Distillery, and went behind the scenes to see how grains, water, and yeast are transformed into wonderful whiskies for us to enjoy. Here, we share our tour in photos.